Work Experience

ATS Life Sciences

May 2025 - Aug 2025

Automation Designer

Skills gained: Autodesk Inventor, FDM and Resin Printing, Mechanical Part Design, and Next-Generation Sequencing (NGS)

- Designed and ran robot, conveyor and plant simulations to determine design feasibility and suggested improvements for multi-million dollar automation equipment

- Planned and conducted tests to determine root causes of error on medical device production lines

- Wrote multiple reports to highlight key findings from production line testing to a multidisciplinary team of 10+ people

- Conducted testing to determine the feasibility of new internal production techniques and presented findings and recommendations to a team of engineers and machinists

At ATS Life Sciences, I worked as an automation designer within the systems design department. During my co-op, I played a crucial role in designing and running tests, summarizing results, and suggesting changes to multi-million-dollar medical automation equipment. Through this role, I was able to conduct many different types of simulations, including robot simulations (ABB Robot Studio), plant simulations (Siemens Plant Simulation), and SuperTrak simulations. In addition to simulation work, I was also able to conduct root cause analysis on large production lines, where I was able to increase the pick and place success rate of the system from 30% to >99%.

Triton Genomics

Sept 2024 - Dec 2024

Biomedical Engineering Intern

Skills gained: Autodesk Inventor, FDM and Resin Printing, Mechanical Part Design, and Next-Generation Sequencing (NGS)

- Designed and tested parts using Autodesk Inventor to increase usability

- Used rapid prototyping methods including FDM and resin printing to test designs and analyse the usability of devices

- Redesigned, tested, and printed gasket moulds to decrease processing time and material waste by up to 50%

At Triton Genomics I was responsible for designing and prototyping a device used for NGS library preparation. In this role, I was required to use Autodesk Inventor to create models of parts and assemblies for the device. I also researched and designed solutions to multiple issues that arose when using the first prototype of the device. During my time in this position, I also redesigned molds for creating gasketing which helped reduce preparation time and material waste, and had hands on experience with rapid prototyping methods including FDM and SLA printing.

Multimatic

Jan 2024 - Apr 2024

Test Lab Technician

Skills gained: Microsoft Excel, Photography, MIG Welding, and Power Tools

- Organized and planned out tests daily by communicating with other co-op students to help keep testing on track which increased the quantity of parts that could be tested daily

- Performed updates to the structure of Excel sheets used to track testing data which increased tracking accuracy

- Took photos of fixtures using a DSLR camera and updated the server with new images to decrease the setup time of the testing fixtures

At Multimatic Dynamic Suspensions I was responsible for testing control arms and ball joints to ensure that they were meeting design requirements. I was given production parts and parts in development and conducted torque, articulation, and leak tests on them so their designs could be updated or the manufacturing process could be modified if something was wrong. I was also responsible for taking parts that were delivered to me, checking what tests needed to be done on them on the company server, and then executing the required tests. This experience helped me learn about working in mass manufacturing environments and the importance of quality assurance testing

Delfs Engineering

Feb 2022 - Present

Full Stack Developer

Skills gained: HTML, JS, Tailwind CSS, Vue JS, Claris Filemaker, and Firebase

- Attend daily standup meetings to review projects and keep deliverables on track

- Quickly learn and integrate APIs and technologies into client applications

- Communicate with clients biweekly or monthly to demo, review, and start sprints on web applications which greatly increased client satisfaction

- Code with a team of seven developers on multiple projects simultaneously to ensure deliverables are finished on time

Projects

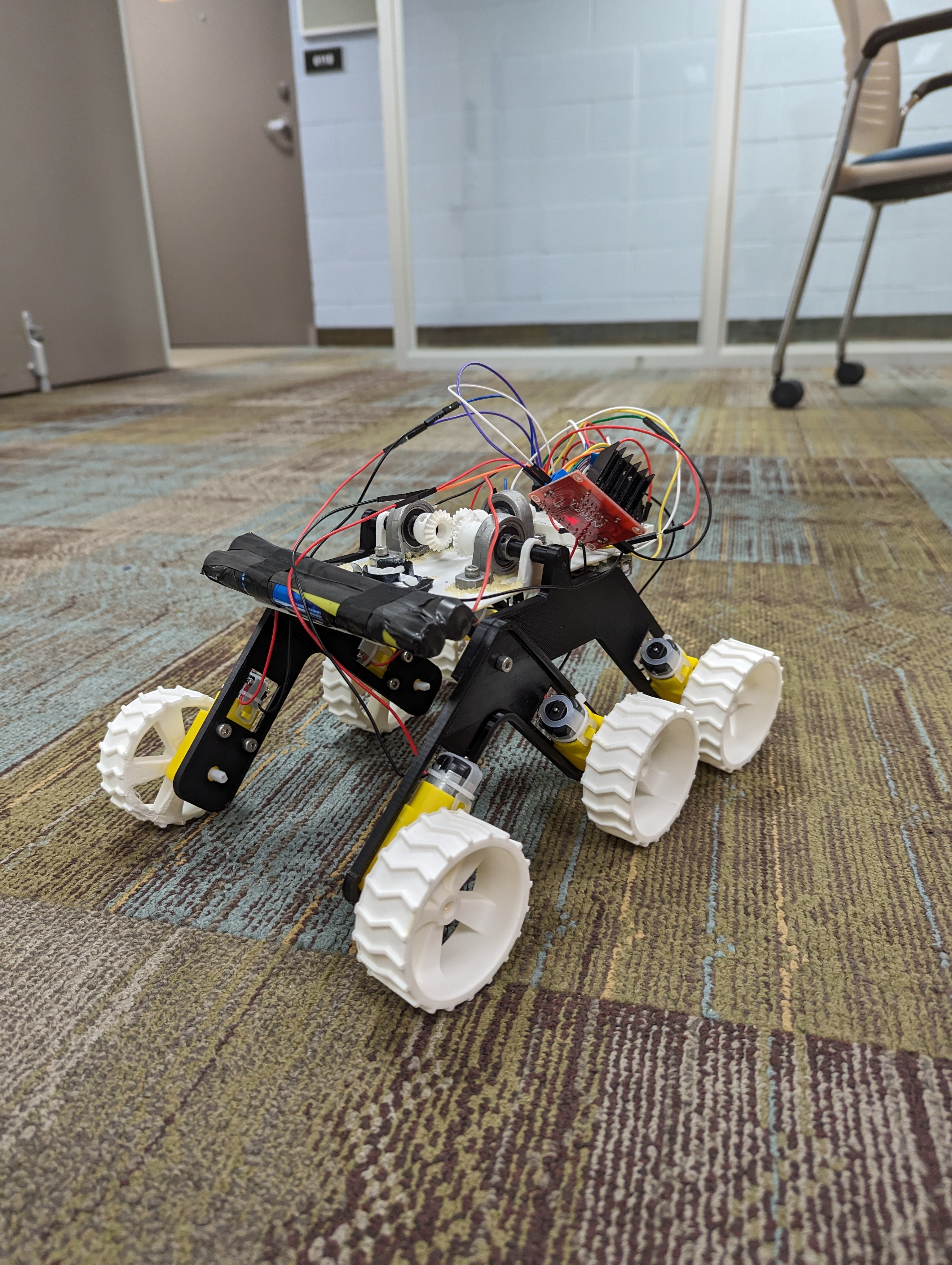

Bluetooth Rover

Skills gained: C++, Soldering, Solidworks, 3D Printing, Working with Arduino, Motor Controllers, and bluetooth Modules

During my first Co-op term I wanted to further expand my skills and knowledge, so I partnered with another co-op student to create a bluetooth controlled rover. The entire rover was modeled in SolidWorks and the majority of the parts were 3D Printed. The main C++ program is able to connect with the rovers HC-05 bluetooth module and transmit data from a game controller to control the robot's motors and camera stand. The rover uses an Arduino uno to read data from the bluetooth module and control the L298N motor controller and the two micro servos on the camera stand.

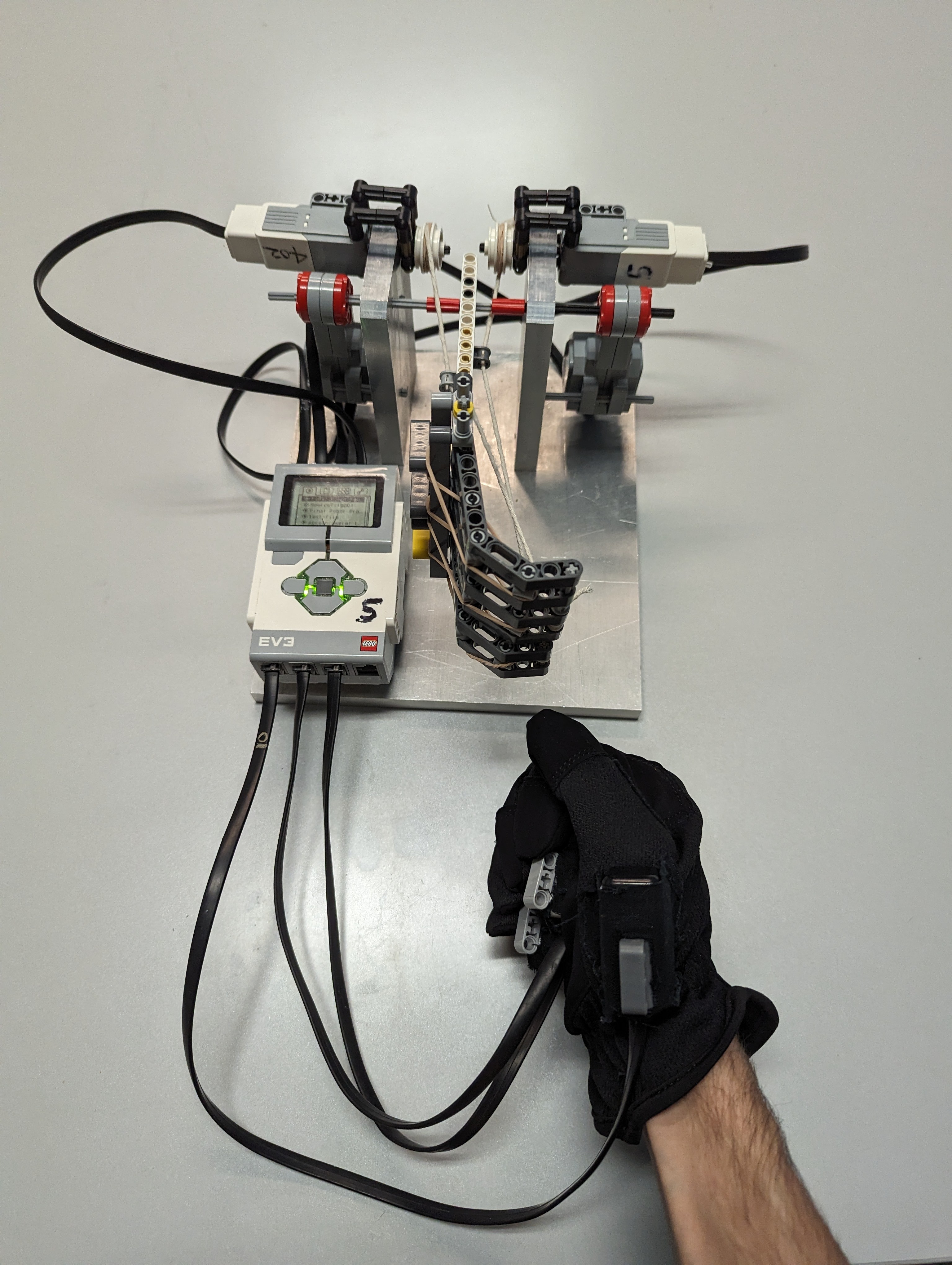

Rock Paper Scissors Robot

Skills gained: Machining, Solidworks, Robot C

For my final 1A project I worked with a group of three other students to help code and build a robot that plays rock, paper, scissors. The base was machined from a plate of aluminum and the rest of the robot was constructed using Lego EV3 parts. The robot used four motors to control the arm and finger movement and also contained two touch sensors and an accelerometer to read the user input. The entire program was written in Robot C and is able to generate moves, keep score, and play an animation when the game finishes.

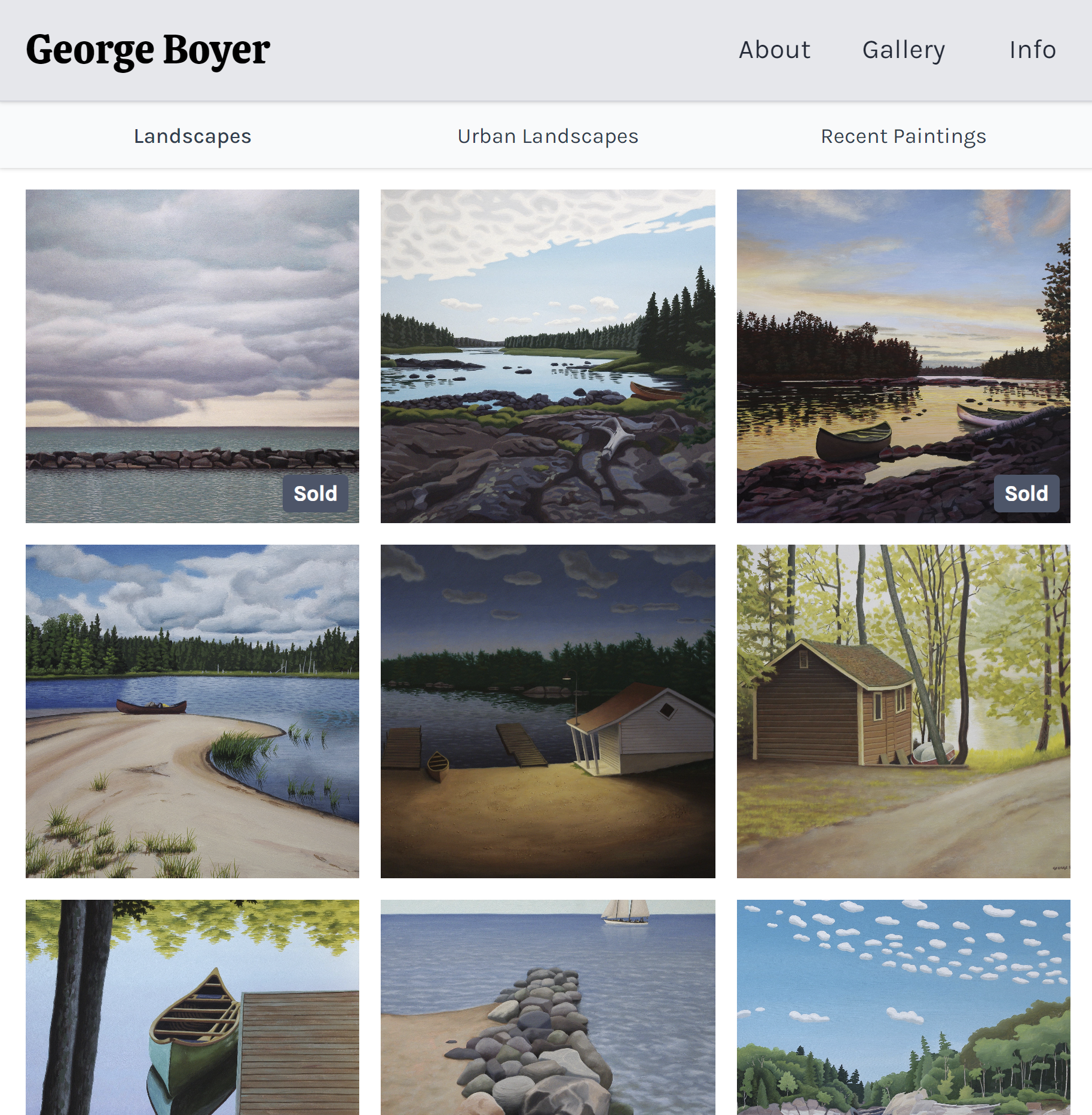

Portfolio Website

Skills gained: Mongo DB, Node JS, REST, HTTP Protocols

The purpose of this app was to dynamically display a collection of paintings and allows admins to easily edit site data. This app was developed using Vue.js, Node.js, Express.js, and Mongo DB. During the project I learned and integrated Courier for sending user emails, and Dexie to cache site data

Skills & Awards

Programming

- HTML & CSS

- Vue JS

- Next JS

- Node JS

- C++

- Mongo DB

- PostgreSQL

- Claris Filemaker

Design

- SOLIDWORKS

- AutoCAD

- Inventor

- OnShape

Awards & Certifications

- Certified Solidworks Associate

- 2023 Solidworks Basics Training

- 1A, 1B, 2A Term Deans List

- 1A, 1B First in Class Scholarship

- Governor Generals Bronze Medal